Getting Started with RFID

投稿人:DigiKey 欧洲编辑

2012-08-16

If you have ever slapped a travel card on a reader as you pass through the gates of a mass transit system, or used a dash-mounted pass to pay a highway toll, you will know that radio-frequency identification (RFID) technology is increasingly ubiquitous. This feature looks at ways in which developers can use RFID technology in their applications, and considers some of the design issues involved.

Given the relative maturity of RFID technology, there are many ways in which developers can employ it in their systems. Those who are simply in a hurry to get the function implemented can buy ready-built transponders and modules and then build systems around them, adapting the design and approach to the limitations of using these general-purpose building blocks.

For more demanding applications, with longer leadtimes, development systems and evaluation boards are available that designers can use to explore the issues involved in creating their own RFID systems. Those who want the ultimate flexibility can choose from a range of basic components, such as RFID ICs, tags, and antennas and build them up into systems tailored to their needs.

The basics

RFID technology is divided into two major categories, depending on whether the tag is active, powered by a battery or other source, or passive, relying on an electromagnetic field to induce enough current in a pick-up loop to broadcast a small packet of identification data. [Some tags that work at microwave frequencies rely on backscatter instead.] The trade-offs here are obvious - simple passive tags are cheaper and do not need maintenance, but active tags can broadcast more data, and usually over a greater distance.

The RFID tag usually includes an integrated circuit connected to the antenna, which is sometimes little more than a track of conductive ink printed on a substrate, or a trace on a PCB. The RFID reader is usually a small radio transceiver, managed by a microcontroller, which interrogates the tag by transmitting an RF field to induce a current in the tag antenna and so provide its power, and then sends the tag a command to tell it to transmit its information back to the reader. The data in the tag usually includes a unique identifier that cannot be changed, and user memory that can be read from, written to, and sometimes locked so its contents become fixed.

RFID technology is also categorized by its operating frequency, which usually lies within one of the unlicensed industrial/scientific/medical (ISM) bands, defined at both national and international levels. These bands are unlicensed, but still define operating power limits, an important consideration for designers developing systems to work over longer distances where factors such as antenna design, transponder power consumption and receiver sensitivity need to be taken into account. Since every bit of information takes energy to transmit, designers also have to trade off the amount of data they want their tags to hold with the amount of energy they can afford to use to access that data. Holding large amounts of data will also increase the memory requirements of the tags, making them more costly. Many tags also need some sort of security function, so that the data they carry cannot be intercepted in transit by an unauthorized third party, or replaced to falsify a record.

The building block approach

If you want a lot of the work of implementing RFID done for your design, various modules and transponders are available.

DLP Design offers the DLP-RFID1, a single-channel 13.56 MHz reader and writer module, which works with tags conforming to the Tag-It, ISO18000-3, and ISO15693 RFID communications protocols. Powered from a USB port, the module includes an antenna with a sensing range of up to 4 inches and a pass/fail beeper. Demonstrating just how commoditized the technology has become, the module is available both as an unpackaged PCB for OEMs, and as a packaged module for sale to end users which also includes a USB cable and a set of five ‘peel and stick’ RFID tags. The module comes with development software and drivers for Windows XP, 2000, 98 and Me. DLP Design says it is most suitable for applications such as library-book tagging, inventory tracking in pharmacies, personal identification, baggage tagging and timing in sporting events. It even works with some laundry tags.

SkyeTek is taking RFID even further with its SkyeModule M7, an RFID reader built on a PCB that is smaller than a matchbook. The part works with tags operating from 862 MHz to 955 MHz and has an effective read range of up to 2 m with an external, linearly polarized antenna that connects through a 50 ? port. Versions of the module are available with TTL or USB host interfaces. The operating voltage is 5 V and SkyeTek claims the module has a current draw in sleep mode of 10 mA. At this size, the company says the reader could be used in printing and encoding, handheld reading/encoding, inventory management, patron management, access control, and asset management. A development kit is also available to get users started with the module. It includes reader modules, sample tags, an external antenna, connectors and cables, demo software, device drivers, design guides and application notes.

Development systems and evaluation boards

The applications for RFID are so diverse, leading many manufacturers to provide comprehensive development systems and evaluation boards so that designers are well supported as they explore their niche application areas.

At the level of individual ICs, companies such as STMicroelectronics provide evaluation boards carrying their transceiver ICs and enough support circuitry to enable users to work with the parts and develop the code needed to control them.

The DEMO-CR95HF-A-ND board is a demonstrator for STMicroelectronics’ CR95HF, a 13.56 MHz transceiver IC. The board includes the multiprotocol transceiver IC, a STM32F103Cb 32-bit microcontroller, and a 47 x 34 mm antenna implemented as a circuit trace on the PCB and its related tuning components. A USB port supplies power and communications with a host computer. There is also a hard reset button for the microcontroller, an LED that shows when the board has been initialized, and a JTAG port for updating the microcontroller’s firmware and handling debug. The board comes with two different types of tags, one mounted on a 45 x 75 mm antenna and the other on a 15 x 15 mm double-sided etched antenna. Demonstration firmware on the microcontroller enables communication with the host PC over the USB connection, while software for the PC handles basic communications with ISO15693 and dual-interface EEPROM tags.

The component level

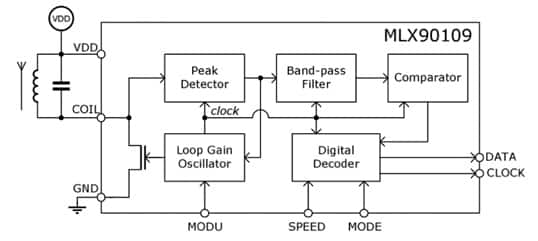

At the component level, companies such as Melexis offer parts including the MLX90109EDC, an integrated RFID transceiver that operates over a range of 100 KHz to 150 KHz. The company says it is suitable for use in applications such as vehicle immobilizers, portable readers, access control and household appliances.

The part uses an external coil inductor and capacitor, connected as a parallel resonant circuit, to set both the carrier frequency and oscillator frequency of the transceiver, which means it does not need an external quartz reference oscillator. This also means that the antenna is always perfectly tuned to resonance, because it defines the carrier frequency, so the part does not have ‘zero modulation’ issues that can occur in other devices. These issues occur when the tag does resonate properly, but no amplitude modulation is detected at the reader coil.

Figure 1: The Melexis MLX90109EDC RFID transceiver uses an external coil inductor and capacitor to set both its carrier frequency and oscillator frequency.

There is a simple power-down mode, and the part can also be set up to decode the signal from the transponder on-chip to make interfacing with an external microcontroller over a two-wire serial bus much simpler. For really low-cost applications, the transponder signal can be left undecoded, and is then presented on a single-wire interface.

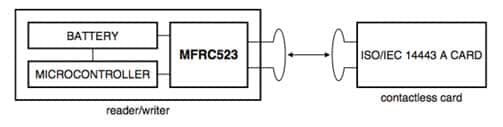

The usefulness of RFID has led to the emergence of standards for particular applications areas, such as NXP’s MIFARE system, which is widely used in contactless payment card systems. NXP’s MFRC523 is an integrated reader/writer chip, operating at 13.56 MHz, which supports all the variants of the MIFARE protocol. Its internal transmitter circuitry can drive an antenna directly, without additional active circuitry. The receiver module can capture, demodulate and decode signals from MIFARE-compatible cards and transponders, and includes support for the more sophisticated features of the standard such as ‘anti-collision’, which sorts out what happens when the reader picks up signals from two tags at once.

Figure 2: The basic set-up of NXP’s MFRC523 MIFARE chip.

The part can also support the higher data-rate communications defined in the MIFARE protocol, up to 848 Kbit/s in both directions. As is usual for such devices, the part has an SPI serial host interface, a serial UART, and an I2C interface.

Antenna integration

Many RFID systems are designed to be as discrete as possible; travel passes are stuck in wallets, or a toll pass is tucked out of the way on an automobile dash. The challenge for designers who want to create such discreet-use cases is that it can make detecting signals from the RFID tags more difficult. This is where external antennas come in, either to boost the sensitivity of the transceiver or to enable the antenna and the module it is driving to be positioned separately within the equipment.

For example, DLP Designs’ multi-channel 13.56 MHz tag reader/writer module, the DLP-RFID1, can read the unique ID codes of up to fifteen tags at once. It is powered by USB and offers a simple interface to PCs running various versions of Windows or Linux. The module has a built-in antenna with up to a 4 inch read range. Similar modules offer connections for multiple antennas, such as the DLP-FANT, a cylindrical-shaped ferrite antenna built on the end of a coax connector. It is designed for use where space is at a premium, and offers a read range of up to 1.25 inches. It needs a coax cable with a reverse-polarity SMA connector on one end to connect to the DLP-RFID-LP8C reader. (DLP Design offers a suitable 3-foot cable under the DLP-COAX1 part number.)

Figure 3: DLP Design’s ferrite antenna is designed for use where space is at a premium.

The second antenna, the DLP-RFID-ANT, is more of a patch antenna attached to a 15-foot coax cable with the reverse-polarity SMA connector. It also provides up to 4 inches of read range.

Figure 4: DLP Design’s patch antenna is supplied on a 5-foot cable.

Tags

Cost is key when it comes to tags, and the RFID industry has been working for years to reduce the cost of tags and so make them applicable to more markets. The desire to enter more markets has also led to the development of a great variety of designs, from credit-card shaped transport passes to flexible and waterproof tags for sewing in to fabrics.

For example, Texas Instruments produces a key fob tag, the RI-TRP-WFOB-30, which operates at 134.2 kHz and can be read from within 60 cm, and is offered for use in applications including vehicle identification, container tracking, and waste management. So called ‘glass stick’ tags, such as the RI-TRP-WEHP-30 from Texas Instruments, fully encapsulate the RFID technology in a sealed glass tube which, the company claims, is insensitive to almost all non-magnetic materials.

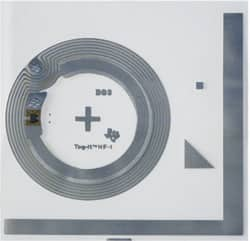

Some tags are developed for very specific applications - Texas Instruments also offers the RI-I17-112A-03, a 13.56 MHz tag that is designed to be laminated into paper, PVC or other substrates, for example in a CD inlay card.

Figure 5: Texas Instruments produces a wide range of tags, including this version designed for lamination into paper labels and inlay cards.

The part is available with six different antenna shapes, and is designed with a frequency offset that accounts for the impact of the surrounding lamination materials on its RF performance.

Conclusion

RFID is a well-established technology, which means that a rich and diverse ecosystem has grown up to serve both the general market and very application-specific markets such as antitheft tagging or pet identification. Alongside support for a wide variety of application areas, the RFID ecosystem also offers lots of entry points for new users, be they experienced designers who are confident to work from the chip level up, or systems integrators who simply want something to plug into a USB port and program using adapted versions of example codes provided in a developer kit or design guide.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国