Fine-Tune Configurable Power Modules Using an Online Design Tool

投稿人:电子产品

2013-09-24

Every system has specific needs when it comes to using power supplies, especially DC/DC converters (both isolated and non-isolated). While hundreds of standard parts are available from a variety of suppliers that can broadly meet the efficiency, density, size, cost, and other key design specifications, some products have very specific requirements. It could be a higher input or output voltage, faster turn-on, or a different current limit that is not part of a standard product offering.

That means either you design in-house or obtain a custom solution. Both of these approaches are costly and time consuming. However, if you can take a standard part and quickly tailor it to your specific system needs, you can save time, dollars, and resources. Vicor has done that by adding user-configurable capabilities to its high-performance VI Chip PRM modules. Although the PRM modules are available as standard parts, a few members have been added with inherent configurability, which can be accessed using the supplier’s online tool suite called PowerBench.

Configurable modules

Vicor’s VI Chip PRM is a very-efficient non-isolated DC/DC converter module series that is capable of both boosting and bucking a wide range of input voltages and providing a regulated, adjustable output voltage. As standalone devices, the modules can be used as non-isolated voltage regulators for myriad point-of-load (POL) applications. However, when Vicor’s PRM is combined with the company’s VTM current multiplier, it can generate a complete isolated DC/DC solution with high efficiency and power density for factorized bus voltage application, or high step-down-ratio DC/DC solutions for isolated POL applications. The VTM module provides point-of-load, fixed-ratio voltage transformation with extremely-fast transient response and isolation to 2,250 VDC.

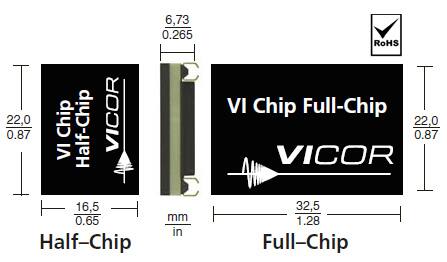

According to the manufacturer, PRM models are compatible with standard pick-and-place and surface-mount assembly processes. Through-hole options are available only for full-chip packages. As shown in Figure 1, the PRM modules come in both full- and half-chip packaging formats. While half-chip packages measuring 0.87 x 0.65 x 0.265 in. (22.0 x 16.5 x 6.73 mm) can convert up to 500 W at over 97 percent efficiency and at unprecedented power densities of up to 1,700 W/in.³ (10³ W/cm³), full-chip modules measuring 0.87 x 1.28 x 0.265 inches (22.0 x 32.5 x 6.73 mm) can deliver up to 250 W with similar conversion performance. The modules offer wide input voltage ranges optimized for 24, 36, 45, and 48 V inputs with regulated 48 V output which can be trimmed across a wide output range.

Figure 1: PRM modules come in both full- and half-chip packages.

To deliver higher efficiency at high output power with high power density, the customer-configurable PRM modules incorporate high-frequency ZVS buck-boost technology. The use of ZVS topology fosters high-frequency operation that maximizes efficiency by minimizing the significant switching losses associated with conventional buck regulators using hard-switching topologies. Concurrently, high switching frequency also reduces the size of external filter components to boost power density while enabling fast dynamic response to line and load transients.

An online design tool

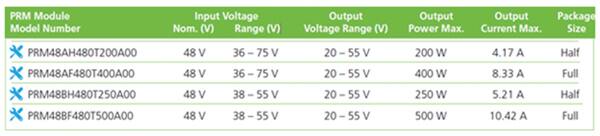

Currently, there are four user-configurable members in the PRM family as depicted in Table 1. Though the nominal input for all four configurable models is 48 V, the input voltage ranges are either wide or narrow. For instance, models PRM48AH480T200A00 and PRM48AF480T400A00 handle an input range of 36 to 75 V, while PRM48BH480T250A00 and PRM48BF480T500A00 offer an input range of 38 to 55 V. According to Ian Mazsa, manager of the VI Chip Product Line at Vicor, what makes the configuration of the PRM possible is the inclusion of a microcontroller within each configurable PRM. As a result, designers can access the internal firmware of the PRM module using the company’s online design tool suite called PowerBench, explains Mazsa. “The tool allows the designer to specify parameters that are programmed into the product during manufacturing,” he adds.

Table 1: PRM modules can be further configured using the PowerBench design tool.

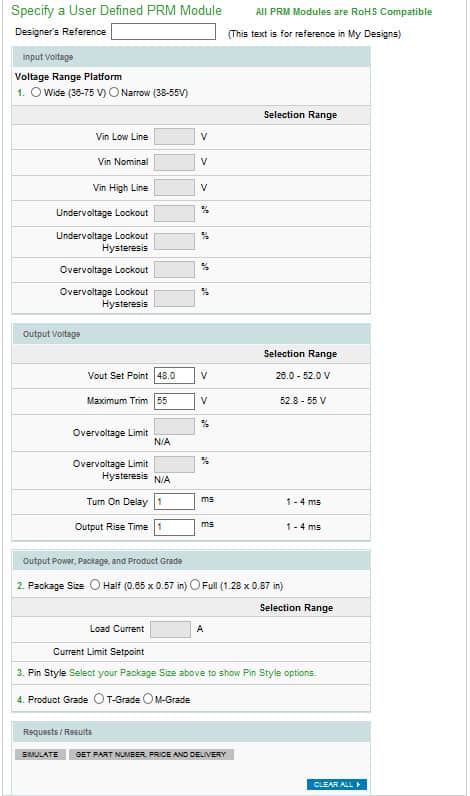

As per Vicor’s VI Chip product manager, the easy-to-use PowerBench user interface (Figure 2) gives designers the flexibility to fine-tune input and output voltage parameters with the ability to specify limits on undervoltage and overvoltage lockout, including the output current limit. In addition, designers can modify turn-on delay and output-rise time. “All these changes can be realized without using any external circuitry,” notes Mazsa.

In essence, to configure a PRM, the user first selects the desired voltage range, wide or narrow. Then, the engineer fills in the input voltage parameters, such as low-line input, nominal, high-line input, under-voltage lockout, under-voltage lockout hysteresis, overvoltage lockout, and overvoltage lockout hysteresis, as shown in Figure 2.

Next, the user chooses output parameters like VOUT set point, maximum trim, turn-on delay, and output rise time. Upon choosing the output parameters, the user then picks the package size, depending on the output power requirement, and the temperature grade (T or M) for the configured product. Once the package size and product grade are selected, the online tool gives a load current range. The designer has to set the load current limit based on the range provided by the design tool.

Figure 2: PowerBench gives designers the ability to fine-tune user-configurable PRM modules.

Once the configuration process is completed, PowerBench will generate a data sheet for the uniquely configured part, as well as a part number with pricing information. The tool allows you to save your custom design parameters online under a My Designs account (the user has to first register to create a My Designs account).

In summary, Vicor’s configurable PRM modules give designers an option to further fine-tune a standard power module to meet specific system needs without using any external components, or making any changes during manufacturing. By using these parts and their associated tool, the power-supply designer can save time, dollars, and design resources. For more information on the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。