Design Solutions for Longer-Lasting IoT Nodes

投稿人:DigiKey 欧洲编辑

2015-12-03

Advocates of the Internet of Things (IoT) invite us to imagine a future where even the tiniest devices are smart and connected, designed to make life easier, more comfortable and to contribute to saving the planet’s resources.

Few, however, will want to imagine a future where tens of billions of remotely installed boxes need to have their batteries changed at regular intervals. Extreme power management using ultra-low-power microcontrollers that draw very low sleep current can allow the IoT to run from a small battery for the lifetime of the device. This may be several years, assuming a low duty cycle. An alternative is to design-in an energy harvesting subsystem capable of powering the device and charging a capacitor or small battery to provide backup.

A key objective of IoT applications is to exploit connectivity to gather intelligence or control devices in locations that have been difficult or uneconomical to reach using other technologies. These connected devices can deliver more value to end users and other stakeholders such as service providers. They may be connected using a technology with native IP transport, such as Ethernet or Wi-Fi, or may be aggregated into an Internet gateway using any of a wide variety of wired or wireless connections such as RS-232, Bluetooth®, Bluetooth Smart or a protocol such as ZigBee® or another dedicated low-power protocol running on an IEEE 802.15.4 radio. The sensors or actuators could be connected individually in remote locations, or may be connected with other nearby devices as part of a mesh network.

In many situations a convenient power supply for the IoT device, such as an AC line or network power like a USB host or Power over Ethernet source, is not available. An independent energy source is needed, such as a primary cell or energy harvesting subsystem. Maintenance-free operation for the intended lifetime of the device is desirable to save the high cost of field-service visits.

If a battery is to be used, the designer must ensure that the total available energy is at least equal to the total energy required by the device throughout its lifetime. When selecting the battery type, factors including cell chemistry influence the discharge characteristic including peak current delivery. As the battery discharges, the circuit will become inoperable when the battery voltage falls below the minimum operating voltage required by the components. The remaining battery energy then becomes inaccessible, unless extra circuitry, such as a boost converter, is introduced. Lithium cell technologies offer good performance in this respect: lithium thionyl chloride batteries are able to maintain a stable voltage of about 3.6 V until the energy is almost depleted, falling quickly near its end of life to a fully discharged voltage of about 2.2 V. Designers should also take into account the battery’s stated maximum discharge current. If the battery is the sole intended power source for the device, it must be able to deliver the peak current required by the load. Alternatively, a short-term storage device having high discharge capability, such as a supercapacitor, may be used to assist the battery at times of peak demand.

An energy harvesting subsystem should be capable of capturing enough ambient energy to cover the device’s needs. Because ambient energy such as light or thermal energy is usually not available continuously, energy harvesting may be used in conjunction with an energy-storage device that is at least able to supply backup power to the microcontroller while the sensor is in power-saving mode. A small rechargeable battery such as the Seiko MS412FE 4.8 mm x 1.2 mm lithium coin cell, which has 1.0 Ah nominal capacity and maximum continuous discharge current of 0.1 mA, could satisfy this requirement. Figure 1 illustrates a charging circuit for the MS battery. The charging voltage, Vc, should be no more than 3.3 V. In this case, a 2 MΩ resistor should be inserted to regulate the charging current. Alternatively, a storage capacitor may be used, but has a faster self-discharge rate than a battery.

Figure 1: Charging circuit for rechargeable lithium battery.

Cost and size constraints must also be taken into account when choosing energy harvesting or battery power. Lithium primary cells are available in a variety of sizes and capacities, including standard button and cylindrical form factors. The Tadiran TL-5101 is a half AA-size 3.6 V battery in an axial leaded package that can be soldered directly to the circuit board or power supply leads. This eliminates the cost of a battery clip, and the extra time overhead to insert the battery manually during final assembly.

As far as energy harvesting is concerned, a kit such as the Microchip XLP 16-bit Energy Harvesting Development Kit can help to accelerate design-in. The kit is based on the PIC24F microcontroller and a solar energy harvesting module with on-board rechargeable thin-film energy-storage devices. The software provided includes charge monitoring, and the main board features a standard PICtail expansion connector that simplifies adding wireless connectivity using an IEEE 802.15.4 2.4 GHz radio module.

Microcontrollers for the IoT Age

The growing importance of careful energy management in IoT applications has driven the development of ultra-low-power design, taking advantage of flexible microcontroller sleep modes to reduce current draw or deactivate unused circuitry whenever this can achieve a net energy saving. A connected sensor that must periodically capture sensed data, perform a small number of processing actions locally, and transmit the result wirelessly to a receiver has a power profile characterized by long periods in sleep mode where power consumption is minimal, with short periods of higher demand as the device is activated to receive, process or transmit data. The application designer’s skill lies in ensuring the low level is as low as possible for as long as possible, and the peaks are as low as possible for the briefest possible time.

Microcontrollers such as Microchip XLP (eXtremely Low Power) devices, STMicroelectronics STM32L lines and Texas Instruments MSP430 devices such as the latest MSP430FG6626 have introduced flexible architectures that give designers more control than typical conventional microcontrollers to power down unused peripherals and parts of the CPU core while continuing to support important functionality. Core-independent peripherals, such as a UART capable of receiving and transferring data packets directly into memory without CPU intervention, help to save energy and also save code space.

Microchip XLP devices such as the 16-bit PIC24FJ256GB410, which is part of the new PIC24 GB4 series, combine features supporting ultra-low-power design with an integrated hardware crypto engine capable of offloading important IoT security tasks from the main processor.

Microcontroller SOS (Switch Off Something)

Whereas conventional microcontrollers usually support only limited power-management modes, usually giving software designers a choice of active, idle or sleep, ultra-low-power microcontrollers support more complex power-management schemes. A multitude of power-saving features cover all aspects of the device, such as the clock subsystem, voltage regulator, and special low-power peripherals like the integrated op-amps of the MSP430GF6266.

Additional control over the clock and voltage regulator, as in the STM32L0 series, gives designers the flexibility to optimize operating speed and supply voltage dynamically to ensure all operations are performed at the lowest power consumption possible within any applicable constraints on execution time. The clock controller provides multiple internal sources, controlled by logic, which designers can use to select a low-, medium- or high-speed path, to allow peripherals to be operated at a suitable speed depending on whether the PCU is active or static. In addition, multiple gates to peripherals provide a convenient and responsive means of deactivating individual peripherals. Devices such as DACs or GPIOs can be halted while pin states remain valid.

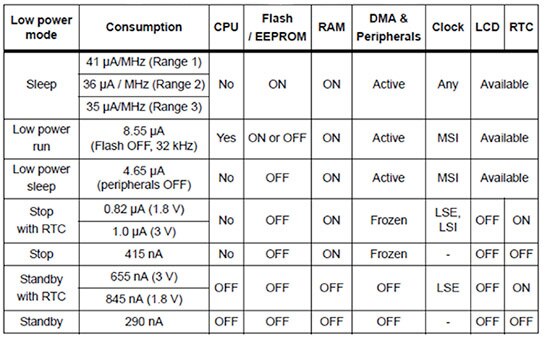

In addition, multiple voltage regulator modes give the choice of Normal, Low-Power or Off to allow multiple Run and Sleep states. Hence, there are Low-Power Run and Low-Power Sleep modes, in addition to normal Run and Sleep modes. There is also an 8 µA Stop mode, in which all clocks are stopped except the low-speed clock. In this mode, the RTC and RAM can also be turned off, reducing the current further to 4 µA. The device can exit Stop mode in 3.5 µs, which allows frequent use of Stop to maximize overall power savings. Even more circuitry can be turned off to save energy: the on-chip Flash can be powered down in any operating mode, and the low-power timers and UARTs can be turned off in Stop mode. In addition, there are Standby modes with RTC on or off. Standby turns off the voltage supply to the core, and also the high-speed and medium-speed clocks, reducing current to 0.27 µA. Figure 2 summarizes the microcontroller low-power modes.

Figure 2: Microcontrollers architected for power-conscious applications such as self- or battery-powered IoT nodes provide multiple power-management modes.

The core voltage can also be scaled dynamically, allowing a choice of voltage ranges down to 1.2 V to maximize energy savings when the performance demands placed on the core are low. The voltage can be scaled up or down quickly, within about 3 µs, which enables fast response to rapid changes in performance demand.

Conclusion

Billions of smart wireless devices such as remote sensors will be connected to the Internet in the coming years. Battery-free operation taking advantage of efficient energy-harvesting technologies offers great environmental credentials. Alternatively, IoT endpoints can be designed to operate maintenance-free for their intended lifetime through a combination of careful battery selection and embedded design leveraging ultra-low-power microcontrollers.

References

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。