Charge Management ICs Optimize Li-ion Battery Effectiveness for Energy-Harvesting Systems

投稿人:电子产品

2014-06-25

Lithium-ion batteries offer an effective solution for storing excess energy and meeting peak power requirements in energy-harvesting applications. Yet, maintaining battery health requires careful attention to voltage levels during charge and discharge operations. Engineers can simplify application of Li-ion energy-storage devices in energy-harvesting designs through use of suitable ICs from manufacturers including Cymbet Corporation, Linear Technology, Maxim Integrated, Seiko Instruments, STMicroelectronics and Texas Instruments, among others.

Energy-storage devices remain an essential component of energy-harvesting applications that must contend with fluctuating levels of ambient energy. In a typical energy-harvesting design (Figure 1), load circuits gain additional power from Li-ion storage devices, including thin-film batteries such as Cymbet EnerChip series and rechargeable coin batteries such as the FDK ML series, Panasonic ML and VL series and Seiko Instruments MS series. By storing excess energy during periods of low power consumption, rechargeable devices provide a ready source of power during periods of low ambient energy or when demand for power peaks due to heavy MCU activity, periodic wireless transmission, and other power-intensive system states.

Figure 1: Li-ion thin-film and rechargeable batteries provide sustained power for periodic peak-demand requirements from wireless MCUs such as the Silicon Labs EZRadioPRO wireless MCU series (Courtesy of Silicon Labs).

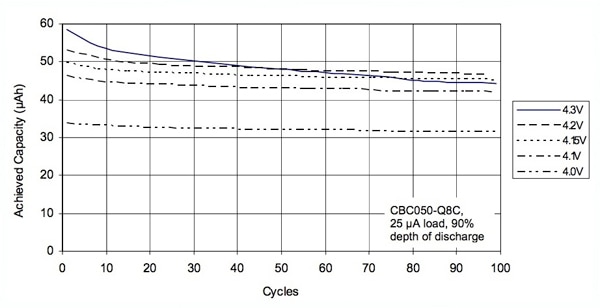

The health and efficiency of these Lithium-ion-based storage devices depends on critically maintaining charging voltage within a narrow window (Figure 2). Voltages outside the operating range can lead to cell deterioration. In fact, even charging voltages that approach the limits of the safe operating range can lead to eventual loss of cell capacity (Figure 3). As a result, charge management circuits are critical in ensuring optimum output and lifetime of these storage devices.

Figure 2: Lithium-ion cells require use of charging voltages within a narrow operating range (Courtesy of Panasonic).

Figure 3: Even within the safe operating range of Li-ion cells, charging voltages that approach the limits of that range can result in loss of capacity over time (Courtesy of Cymbet).

Charge management solutions

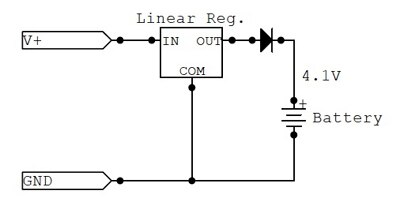

Li-ion cell management circuits typically rely on a constant-voltage source to maintain optimum charging voltage and a load-disconnect circuit to prevent overdischarge of the Li-ion cell. Although Li-ion cells can use a combination of constant-current and constant-voltage charging, Li-ion battery manufacturers typically recommend constant-voltage charging. Consequently, a suitable charging circuit can comprise simply a linear regulator along with a diode to prevent back-discharge (Figure 4).

Circuit designers have a number of options for implementing load-disconnect functionality. Designers can compare battery output against a low-power voltage reference source such as the Texas Instruments LM4051 and Maxim Integrated MAX6037 that provides an output voltage within the Li-ion operating range. When the battery voltage falls below the reference, the circuit can use a FET switch such as the Diodes Incorporated ZXMN2F30FH or Fairchild Semiconductor NDS8434 to disconnect the battery from the load. Similarly, engineers can use power-good signals and undervoltage lockout (UVLO) signals provided by many voltage regulator ICs to control the load-disconnect switch.

Figure 4: The simplest charging circuit for a Li-ion battery comprises a linear regulator to maintain proper charging voltage and a diode with very low reverse-bias leakage to prevent discharge of the battery back through the source (Courtesy of Cymbet).

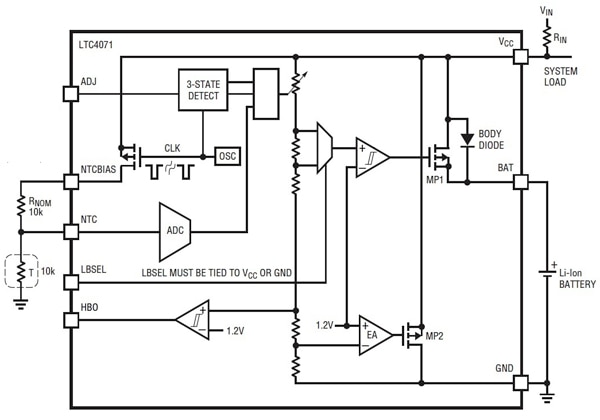

Li-ion charge management ICs integrate the key charging and protection circuits needed to manage Li-ion cells, and provide the extensive functionality needed to optimize cell output and lifetime. For example, the Linear Technology LTC4071 requires only one external resistor to provide a complete Li-ion battery management solution (Figure 5). When the input supply is removed and the battery voltage is below the high-battery output threshold, the LTC4071 consumes just 550 nA from the battery, reducing power requirements in power-constrained energy-harvesting applications.

Figure 5: Li-ion charge management ICs, such as the Linear Technology LTC4071, integrate charging and protection circuitry, requiring minimal additional components to provide a complete Li-ion cell management solution (Courtesy of Linear Technology).

In the LTC4071, if the external Li-ion battery voltage falls below the low-battery disconnect (VLBD) voltage level set by the engineer, the internal PFET (MP1) disconnects the battery from VCC, protecting the battery from overdischarge either by the load connected to VCC or even from the LTC4071’s own quiescent current. In disconnect mode, battery leakage current is below 0.1 nA even at the high end of its operating temperature range.

To protect the external Li-ion battery from overcharging, the LTC4071 reduces the charge current by shunting as much as 50 mA current away from the battery as the battery voltage approaches the float voltage. While it uses an integrated three-stage decoder to provide three programmable float voltages (4.0, 4.1, or 4.2 V), the LTC4071 uses an NTC thermistor to detect high temperatures and automatically reduce the battery float voltage.

Broad functionality

Other devices, such as the Maxim Integrated MAX1737 and Seiko Instruments S-8261, provide outputs for controlling the gate of external FET devices that serve as charge current sources or cutoff switches. For its MAX1737, Maxim Integrated designed the part to use an external dual N-channel MOSFET as a switch and a synchronous regulator that provides charging current or voltage.

The Seiko S-8261 uses separate external FETs for overcharge and overdischarge protection. Here, when the external Li-ion battery voltage exceeds a specified overcharge detection voltage level, the device turns off the charging control FET to stop charging. Similarly, the device turns off the discharge control FET when battery voltage is less than the specified overdischarge detection voltage. The S-8261 uses detection delay timers for each condition to avoid false triggers.

Besides the devices mentioned above, engineers can find Li-ion charge management devices that offer a broad range of features and meet a wide range of functional and performance requirements. For example, the Cymbet CBC3105 combines thin-film energy storage with on-chip power management capabilities in a single integrated device. Featuring sophisticated power management capabilities, other devices such as the Maxim Integrated MAX8601 and the STMicroelectronics L6924 and L6924D are designed to support USB-port charging sources, but can nevertheless serve as effective solutions for power-limited energy-harvesting applications.

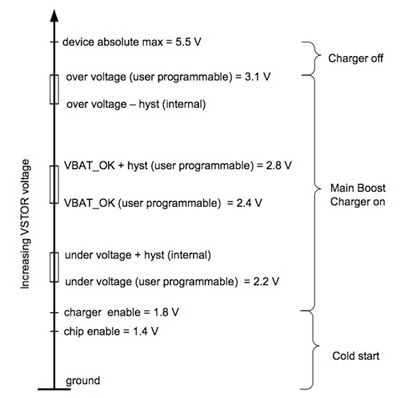

Besides adopting these specialized Li-ion charge management devices for energy-harvesting applications, engineers can turn to specialized energy-harvesting ICs that also support Li-ion charge management and protection. Highly integrated ICs, such as the Texas Instruments BQ25504 and Maxim Integrated MAX17710, extend their integrated energy-harvesting capabilities with a complete set of features required for Li-ion charge management. The TI BQ25504 integrates a high-efficiency DC/DC boost converter with specialized energy-harvesting features such as maximum-power-point tracking (MPPT) to optimize power output from ambient energy sources. In addition, the device supports battery charging and protection with programmable thresholds used for undervoltage and overvoltage protection (Figure 6).

Figure 6: The TI BQ25504 features three programmable threshold voltage outputs that can be used to signal undervoltage, overvoltage, and good voltage — here, showing voltage threshold settings for a typical solar application (Courtesy of Texas Instruments).

The Maxim Integrated MAX17710 is designed to work with a wide range of ambient energy sources and integrates independent functions able to charge an external cell with overcharge protection and able to regulate cell output with overdischarge protection. For charging, the device uses an internal-linear regulator to maintain charging voltage at 4.125 V. If the charging source exceeds 4.15 V, the device begins to limit current flow, and if the charging source exceeds 5.3 V, the device can shunt up to 50 mA to ground to avoid overvoltage operation. For output, the MAX17710 uses an internal low-dropout (LDO) regulator to regulate cell output voltage. If the cell becomes overdischarged, a UVLO circuit disables the LDO regulator if active or prevents it from starting up if already disabled.

The MAX17710 addresses situations where very ambient energy levels cause system voltage to collapse when neither ambient source nor Li-ion storage are able to provide sufficient power to sustain support for the load. In this situation, energy-harvesting circuits can enter into a state where the power system continually tries to support the load but collapses — only to try again and fail repeatedly. With the MAX17710, when power fails in this way, the device disables the output to the load to prevent futile load-restart attempts and to protect the cell from overdischarge. The device remains disabled until it detects that a charge source with a specified voltage level has been connected to the system.

Conclusion

Rechargeable Li-ion batteries can deliver power for peak loads and when energy output from ambient sources falls below useful levels. To maximize battery life and output, however, engineers need to ensure battery voltage levels remain within narrowly defined limits. Designers can easily incorporate Li-ion cell management capabilities using either dedicated charge management ICs or relying on cell charging and protection features integrated in specialized energy-harvesting devices.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国