AC LEDs Gain in Popularity

投稿人:电子产品

2015-10-06

When powered from a mains supply, LEDs require large and expensive drivers to convert the high AC voltage to a low DC voltage. The drivers increase complexity, cost, and the size of the LED lighting fixture, pushing up the prices of solid-state lighting (SSL) and slowing mainstream adoption.

“AC LEDs” offer an alternative approach. Despite the name, these LEDs are not driven directly by a high-voltage alternating current, rather they use a variety of schemes to manage the AC input such that individual LEDs are exposed only to modest current and voltages. However, the elimination of the drivers used with conventional devices has seen AC LEDs start to migrate from niche to mainstream applications.

This article describes how AC LEDs have developed, explains their advantages and drawbacks as alternatives to conventional SSL, and presents some examples of commercial solutions.

Not a drop-in replacement

LEDs, as the name indicates, are a form of diode. To operate, the devices demand a constant (relatively low) biasing (“forward”) voltage to ensure conduction and subsequent emission of photons resulting from recombinations of electrons and holes near the LED’s p-n junction.

Modern LEDs typically require a forward voltage (Vf) between 2.5 to 12 V resulting in a forward current (If) in the 350 mA to 5 A range, although many higher-voltage devices are available. For example, Lumileds’ LUXEON T requires a typical Vf of 2.8 V and can withstand a maximum current of 1.2 A. At a Vf of 2.8 V and If of 700 mA, luminosity is 218 lm and efficacy is 111 lm/W.

Traditional incandescent lighting operates directly from mains AC power and replacement by efficient and long-lived LEDs is made more difficult because of their requirement for low-DC driving voltages. Typically, specialized, expensive, and bulky voltage regulators (“LED drivers”) are required to convert the AC mains to the DC voltages needed to power the LEDs. For example, a driver for an LED-powered 7 W MR16 lamp typically comprises a large electrolytic capacitor and up to twenty other components. Even more components are required in higher-power applications.

While the price is dropping, LED lights are still more expensive than traditional bulbs and anything that adds to the cost of conversion will likely alienate many consumers. That’s provided an incentive for LED makers to come up with cheaper alternatives for certain applications.

Eliminating the driver

While all SSL fixtures ultimately derive their power from the AC mains, manufacturers have worked hard to develop AC LEDs, devices that are able to operate without the need for dedicated LED drivers and hence can be made less expensive than their conventional counterparts.

There are several types of AC LEDs that can be roughly classified into two groups: Low-voltage (operating from 12 to 24 VAC) and high-voltage (15 to 55 VAC). Low-voltage systems have become popular for applications such as outdoor garden lighting, cove lighting, and in retail applications. Such systems are relatively simple, using an electronic- or magnetic-transformer to step down the voltage to that required by the LEDs and a current-limiting resistor to restrict the maximum power applied (Figure 1). Low-voltage AC is typically self-rectified[1].

Figure 1: Low-voltage AC LED systems are relatively simple, comprised of a transformer and current-limiting resistor. The phase-cut dimmer shown here is optional. (Courtesy of Thomas Research Products)

Low-voltage AC LEDs are available from many suppliers. Thomas Research Products offers its LED STAR products that operate from a 12 VAC forward voltage and offer a 75 lm output with an efficacy of 63 lm/W (at 100 mA forward current).

Things are a little more complex for high-voltage AC LEDs. In their simplest form, these AC LEDs use a system comprising two long strings of LEDs, one powered by the negative side of the AC sine wave, the other by the positive. The strings of LEDs can deal with the high mains voltage because the combined voltage drop across all the devices is equal to the supply voltage. Control circuitry is incorporated to keep the current from running too high during the peaks in the voltage curve and damaging the LEDs.

The main drawbacks of these basic systems are poor efficacy, large system size, and design challenges with flicker (see the TechZone article “Characterizing and Minimizing LED Flicker in Lighting Applications”), high total-harmonic distortion (THD), and power-factor correction (PFC).

Seoul Semiconductor has addressed the drawbacks of such systems with its Multi-Junction Technology (MJT), which is based on “stringing” the LEDs together at the silicon level. The silicon dies are made up of “cells” that feature multiple 3.0 V forward-voltage drops (ranging from 12 to 63 V). The company claims that its system overcomes the size, flicker, THD, and PFC issues of other high-voltage AC LEDs through the use of a power-switching IC.

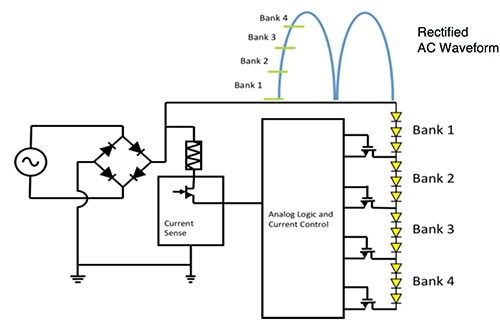

This IC rectifies the input voltage and as the waveform rises, the IC successively switches on banks of LEDs to match their forward-voltage drops to the rectified voltage. As the voltage drops, the banks sequentially turn off (Figure 2). Compared with string systems, whereby all the LEDs in a particular string all turn on and off together, this stepped approach results in more even illumination, minimizing flicker and improving THD and PFC. The “off” time for each cycle is around 1 ms.

Figure 2: Seoul Semiconductor’s AC LED system sequentially switches on banks of LED to minimize flicker.

Seoul Semiconductor’s Acrich2 Chip-on-Board (CoB) modules incorporate the technology and are designed to run from a 120 or 220 VAC supply[2]. The 17 W/120 V version, for example, produces 1300 lm at an efficacy of 85 lm/W (Figure 3). THD is less than 25 percent and power factor is 0.97.

Figure 3: 17 W Acrich2 CoB module produces 1300 lm from 120 VAC supply.

Enhancements ahead

AC LEDs have matured to a point where they are a viable alternative to conventional LEDs for many applications. Both low- and high-voltage types are available and recent developments have addressed earlier problems with flicker, THD, and PFC.

However, manufacturers are not standing still and enhancements in the pipeline include stepping up the 50/60 Hz frequency to 1 kHz to both eliminate detectable flicker and improve efficiencies up to 98 percent.

For more information on the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

References:

- “How Acrich2 Modules Operate,” Dave Neal, Seoul Semiconductor.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。