How Touchscreens Work and Which Technology is Best for Your Project

2021-12-27 | By Maker.io Staff

Touchscreen technology has become increasingly widespread over the last two decades. When looking at touchscreens, we can quickly see why they are a popular method for user interaction. Many touch interfaces are intuitive to work with, and most people learn how to use them quickly. Additionally, manufacturers can use a single display module and then implement the rest in software.

Large button arrays and physical switches require wires and possibly additional components, such as resistors, to function. Using a touch screen in DIY projects may be a reasonable option for your more complicated designs. With all this in mind, this article investigates the most common touchscreen technologies that makers can use in their projects.

Resistive Touchscreen Technology

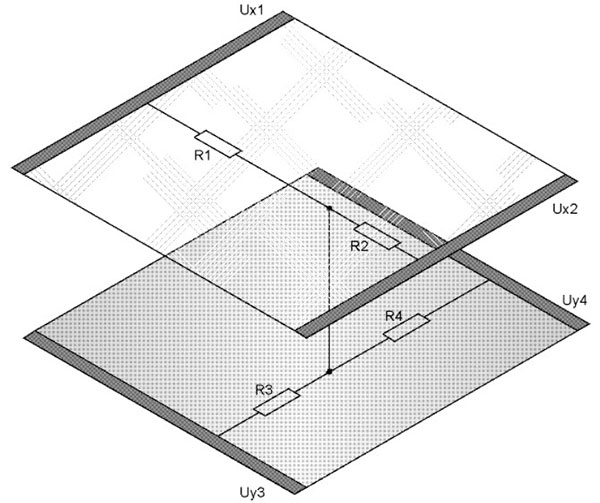

Resistive touch screens are one of the older, widely adopted touchscreen technologies still commonly in use today. Early handheld devices such as PDAs from the late 1990s used resistive touch displays. This touch-display type comprises multiple layers of thin transparent plastic sheets. Two of these layers are coated with an electrically resistive material, and there’s a small air gap that separates them. A small electrical voltage is applied to one layer, and when a user touches the display hard enough to close the gap, the two layers make contact, and the touch controller hardware can detect an input.

This image shows the two resistive layers of a resistive touch screen that detect user inputs. Image source: https://commons.wikimedia.org/wiki/File:Touchscreen.png

This image shows the two resistive layers of a resistive touch screen that detect user inputs. Image source: https://commons.wikimedia.org/wiki/File:Touchscreen.png

This type of touchscreen is simple to use, versatile, cheap, and reliable. In addition, you can use the plastic layers responsible for detecting touch inputs without an electronic screen underneath. You could, for example, use a sheet of printed paper and put it underneath the touch-sensitive plastic layers to create a custom and professional-looking touch panel. Resistive touchscreens can also detect inputs made with pens or when the user is wearing thick non-conductive gloves, for example, when working in a factory.

Unfortunately, you may need quite a bit of force to make touch inputs, which is one reason capacitive touchscreens have taken over in the consumer market. Often, you can also see a fine mesh that sits on top of the display. This type of touchscreen might also require external hardware so that you can connect it to your DIY project. Lastly, the touch-detecting thin plastic layers are prone to scratching and wear out relatively quickly compared to glass.

Capacitive Touchscreens

As mentioned, capacitive touchscreens have become the standard for handheld consumer electronic devices. That is because they are very accurate and reliable when used correctly. Capacitive touchscreens allow users to make precise multi-touch inputs without having to use a lot of pressure. Compared to resistive touchscreens, capacitive touch displays typically use glass instead of plastic, and there are no visible obstructions that could wash out or interfere with the displayed image. In addition, glass is more difficult to scratch, and it also wears out slower than plastic.

Modern consumer devices such as tablet computers commonly use capacitive touch screens. Image source: https://pixabay.com/photos/tablet-touch-screen-reading-glasses-600649/

Modern consumer devices such as tablet computers commonly use capacitive touch screens. Image source: https://pixabay.com/photos/tablet-touch-screen-reading-glasses-600649/

Capacitive touchscreens consist of an insulated carrier, such as glass. That carrier material gets coated with a transparent conductive layer. When a user touches the display, they distort the screen’s electrostatic field, which the touch input controller detects as a change in capacitance.

One major downside of this technology compared to resistive touchscreens is that capacitive touch displays are more likely to shatter when dropped. In addition, the technology itself requires more sophisticated hardware to detect touch inputs, and it’s thus more expensive than resistive touch displays. Last, capacitive touch displays can’t detect non-conductive objects such as regular ballpoint pens, neither do they work when used with most conventional gloves.

Infrared Touchscreen Technology

This technology is lesser-known to most of us because it’s relatively rare in consumer electronics. Infrared touchscreens have an array of IR LEDs and IR receivers running along each edge of the touchscreen. Two sides, for example, the bottom and the right side of the display, contain IR LEDs. The opposite sides have matching IR receivers in place. When an object touches the screen, it disrupts the beam of one or more LEDs, and the receivers can detect the missing IR waves and detect touch inputs.

As mentioned, this technology is quite rare. However, there have been a few products that used this technology throughout the past few years. One such example is the lesser-known Microsoft PixelSense touch-table. Either way, these touchscreens don’t require any modifications to the glass surface. The IR LEDs and receivers sit in front of the display. Therefore, the glass can be sturdier and less susceptible to breaking compared to capacitive screens. IR touch displays respond to touch inputs incredibly well, as small objects will already deflect the light coming from an IR LED. This sensitivity also means that infrared touchscreens can detect any opaque objects, not just conductive ones.

However, the high sensitivity also means that the display will often erroneously detect inputs caused by dirt or by coming too close to the glass without touching it. In addition, it's challenging to choose the correct number of LEDs and sensors, as the right choice depends on various factors, such as the user’s finger size.

Summary

Resistive and capacitive technologies are two frequently used methods for touchscreens in DIY projects. Note that IR touch displays are a somewhat exotic technology, and makers and hobbyists don't use them very often.

You’ll most likely have a hard time finding a touchscreen that is not capacitive. These displays are also reasonable for outdoor applications, as the glass panel is durable, not susceptible to heat and UV exposure, and scratch-resistant.

You’ll most likely have a hard time finding a touchscreen that is not capacitive. These displays are also reasonable for outdoor applications, as the glass panel is durable, not susceptible to heat and UV exposure, and scratch-resistant.

As a bottom line, resistive touch technology is incredibly versatile and best used whenever you seek a cost-effective and reliable solution that can detect non-conductive objects such as pens. Capacitive touchscreens are perfect for consumer devices, as they require little pressure to operate and are very accurate. However, the technology is more complicated, and it can only detect conductive objects. IR displays are rare but very easy to understand. These displays respond to inputs very well, so much that they can erroneously detect dirt as inputs.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.