制造商零件编号 507302B00000G

HEATSINK TO-220 2.5W LOW PROFILE

Boyd Laconia, LLC

In this blog post, we will be going overheat sinks, the chemistry and science behind them, and why we use them in some electrical applications!

A major concern in a lot of electronics is excess heat energy as a result of electrical current flowing through our devices. You may have noticed that after using your laptop or your smartphone for a long time, your device might feel a little warm, and this can be due to a multitude of reasons: an overworked CPU, a strained battery, or more commonly, using the device for too long.

Generally speaking, your phone and/or laptop will be fine after cooling down without any permanent damage from the heat, as long as there isn't an extreme level of heat. However, with devices that are more sensitive to heat, this can be a major concern, especially if their performance gets dampened. For big CPUs, this excess heat can fry the internal components, which can seriously damage your computer.

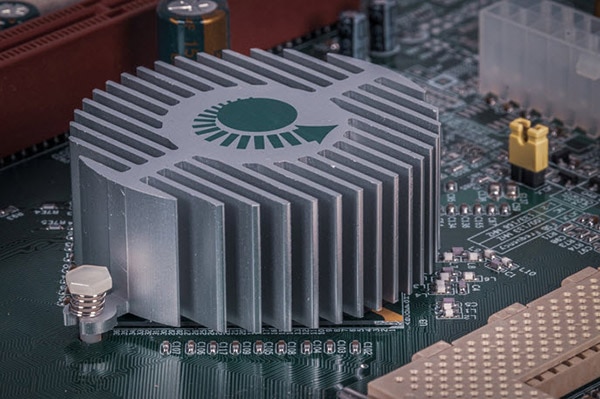

Here's where heat sinks come in!

There are a couple of elements to consider for a great heat sink:

So, where are some applications of heat sinks in our everyday world? In reality, they are so important that they are seen in almost any real-world application, from HVAC systems to heating and cooling systems in power plants and in many consumer electronics.

In summary, heat sinks are used to disperse heat in the system they are deployed in to improve performance, and reliability, and prevent premature failure of electronic devices, meaning that your devices can be less frequently replaced/fixed and will have a longer life span.

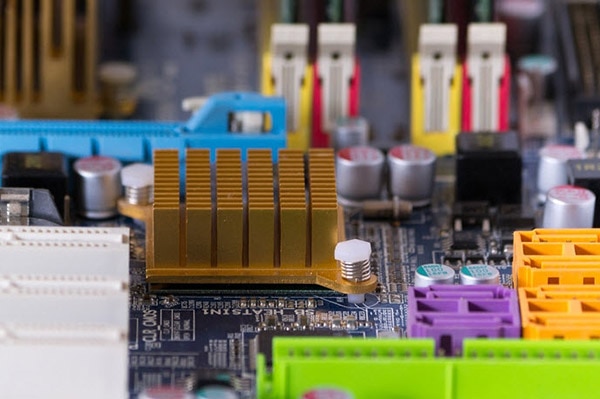

A quick example where a heat sink can be quickly applied is a simple voltage regulator; unlike buck converters, voltage regulators are notorious for dissipating a lot of heat, especially when there's a high voltage differential between the input voltage and the voltage rating of the regulator.

A quick solution to this would be to use a heat sink to help ensure the voltage regulator has a way of dissipating the heat. With just a few extra cents, the voltage regulator can last a lot longer and maintain a more constant performance throughout its lifetime.

That's all about heat sinks today! If you find this blog post informative, please share it with your friends!