Practical 3D Prints for Everyday Problems

2020-03-16 | By Don Johanneck

How often do we find broken or worn-out plastic components such as a lever, cam, or bracket inside of our favorite gadget or gizmo? Even in the age of the internet where all things are searchable, the replacement part fails to materialize, or shipping costs are four times more than the item itself. Fortunately, we also live in the age of rapid prototyping machines that are affordable and use readily available materials making that hard-to-find part not only a reality but potentially even better than the original.

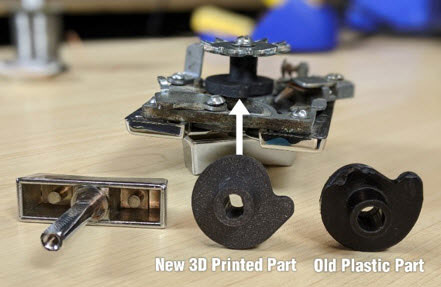

3D printers allow users to not only create original designs but also re-create obsolete ones using online or professional drafting programs and just a few inches of various types of filament. Recently, DigiKey personnel noticed an accumulation of crank-style candy vending machines from the employee breakrooms that were out of order. Inside the machine, a plastic cam attached to the crank handle failed due to design issues that left the part vulnerable to rounding out of the double-D drive slot. See figure 1.

Figure 1

In short order, a replacement was drawn, printed, and tested using a 3D Printer and PLA filament, yielding a functional part with a longer drive profile. See figure 2. In this case, the original part design was improved to prevent the same type of failure in the future which is another benefit to in-house 3D part creation.

Figure 2

Once obsolete machines are now serviceable and back in action dispensing treats. This is one of many instances where making your parts is invaluable. Our homes are filled with components in appliances, toys, tools, and small machines that can be replicated using 3D printers.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.