Trends in Interconnect for LED Lighting Systems

投稿人:DigiKey 欧洲编辑

2012-11-06

The rapid expansion in the use of LEDs for lighting applications has been well documented. Research firm Strategy Analytics estimates that in 2011, the global market for lamps and luminaires based on LEDs grew by 69 percent to $9.4 billion, and that growth will continue through 2016 at a sustained rate of around 20 percent per year.

Increasingly, there is much more to this market than simply replacing incandescent light bulbs – although this remains an important consideration. LEDs are now being pressed into service in premises lighting in offices and retail outlets, in street lighting, in the automotive industry, and a broad range of aesthetic and interior design situations such as display cabinets and commercial refrigeration units.

As a result, LED lighting systems present an increasingly diverse range of requirements for the designer. Most are space-constrained in some way; many involve low voltage and high current, and therefore need to dissipate significant amounts of heat and withstand elevated temperatures over long periods; there is often a need for environmental sealing for performance and safety reasons. The sector is generally cost-sensitive; and yet the majority of applications need to conform to safety and standardization requirements, whether they are used in public spaces or domestic environments.

These design constraints extend from the actual LEDs and drivers used, to the critical interconnections employed within the system. In many cases, designers will elect to use a general-purpose connection system, or at best one designed for power distribution: but in many situations – for instance where the relatively complex electronics associated with LEDs must be fitted into the established form factor of an incandescent lamp – this may be impossible. As a consequence, connector manufacturers have introduced a number of products specifically optimized for use in lighting.

Figure 1: TE Connectivity’s Nector S line is specifically designed for lighting applications.

For example, TE Connectivity provides a wide range of interconnection solutions that are specifically optimized for solid state lighting applications. These include the Slimseal SSL low profile, single row sealed connectors developed for use both indoors and outdoors; poke-in connectors that eliminate the need to hand solder wires and therefore reduce assembly costs; and the Nector S line series, a small power-to-luminaire interconnection system designed to meet the lighting industry’s need for a compact, easy-to-install interconnect solution.

Part of the Nector series, the 7.5 mm mini HVL connector system is a two-position appliance wiring system, developed specifically to conform to the lighting system requirements specified in IEC 60320. It includes the coupling (plug and outlet), a six-way distributor with optional switch function, and various accessories. Options include PCB header, bus bar and chassis mount variants, and designers can also order ready-made cable assemblies based on the system.

The system is aimed at the full range of lighting applications, including wiring in kitchen and bathroom furniture, general-purpose household wiring systems, power connection and coupling between lamps, and mountable lighting such as fluorescent tubes and energy-saving lamps. As well as its use in the domestic context, the system is well suited to use in offices and retail premises. Furthermore, because of its small (7.5 mm) outer plug diameter, HVL connectors can easily be fitted through 8 mm furniture holes, providing an unobtrusive solution for display systems, including vending refrigeration units, which require a sealed coupling.

Constant current strings require custom solutions

One of the most common requirements for LED designers is to interconnect a series of boards in a planar arrangement to create a multi-LED lighting system, driven by a single constant current power supply. As well as providing board-to-board (BTB) connection, power needs to be brought in to the first board in the string via a wire-to-board (WTB) connector, and, if all the boards are to be identical, the final board will need some kind of termination.

Several manufacturers have devised systems to accommodate these requirements, in particular focusing on providing as much commonality of components as possible, and ensuring that the connectors are physically small, so that the risk of light shading is eliminated.

Examples of this type are AVX Corporation’s 9159 and 917x series. The 9159 series is a board-to-board (BTB) connection system that is designed specifically to facilitate end-to-end stacking for applications that combine multiple LEDs into a single lighting unit. Various options are available, including a miniature version with 10-cycle durability for applications that require reparability and 125 V/5 A per contact; and a 250 V/3 A per contact version for cost sensitive applications that use a standard PCB and require high contact force.

A further variant includes a right-angled connector option that allows boards to be configured in a perpendicular arrangement, and the series also includes a wire-to-board connector that mates with the standard board-to-board connector and features a locking latch.

Figure 2: AVX’s 9159 series of board-to-board connectors.

For wire-to-board (WTB) applications, the 9175, 9176 and 9177 products all provide a gas-tight termination and UL94-V0 compliance (the highest level of flame retardancy available). All are available with automotive level testing, while the 9176 is available in a low-profile version.

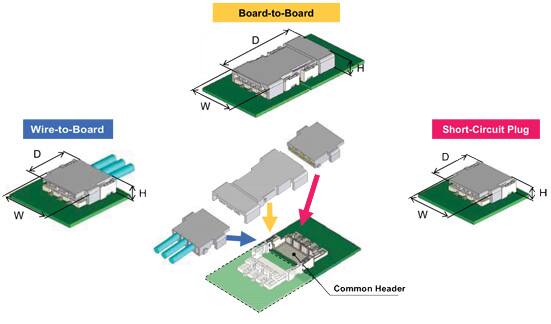

For similar applications, Hirose provides the DF59 series, featuring an ultra-low profile design with a mated height of only 2.48 mm that minimizes shadowing. Three types of plugs – board-to-board, board-to-wire, and short circuit – can mate with the series’ single common header, reducing inventory and increasing design flexibility. The system utilizes a positive “swing-lock” engagement for board-to-wire connections that provides strong plug retention against cable pull, while for board-to-board connections, a ±0.5 mm ‘floating’ facility in all directions produces a stress-free contact in the common co-planar board arrangement, even under conditions of thermal expansion. Operating temperature range is -35°C to 105°C and the products are certified to UL94-V0.

In electrical terms, the terminals feature two points of contact and can accommodate high currents of up to 3 A: a Short-Circuit Pin connector allows the termination of an open circuit, and again will typically be used at the end of a series of connected circuit boards.

Figure 3: Hirose’s DF59 system allows wire-to-board, board-to-board, and short-circuit connections via a common PCB header.

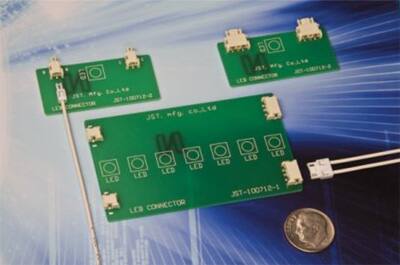

For these applications, JST offers the LEB Connector range, a low profile connector system also specifically designed for LED lighting applications, with both wire-to-board and board-to-board options. With a height of 2.7 mm, this surface mount connector is low profile and space saving, providing flexibility for various LED applications that require high performance connectors in tight spaces. A unique fork type contact provides a stable contact performance.

Figure 4: The LEB series of connectors from JST.

Replacing incandescent bulbs presents special challenges

As we have already observed, the need to fit LED electronics into the form factor of an incandescent bulb or fitting presents its own challenges. The ES3 series from JAE is a two-contact card edge connector specifically designed for use in such LED bulb and LED lighting devices, to allow direct connection between the power converter board and LED mounting board. It has a low mounting height of 1.65 mm, a voltage rating of 200 V and current-carrying capacity of 2 A per contact. A mechanical lock ensures secure mating in environments that are prone to shock and vibration, and the use of a bottom-mating design conceals most of the connector body under the LED board. The receptacle insulator is made of white LCP for heat and light resistance and the entire assembly is rated for operation from -40 to +105°C.

Figure 5: The ES3 from JAE is specifically designed for use in light fittings and LED bulbs, to allow direct connection between converter board and LED mounting board.

General purpose connectors

LED lighting shares many common features with other applications: in particular the need for small size and weight, ease of assembly and low-cost. A number of more general-purpose wire-to-board solutions fit the bill.

One example is the DF57 from Hirose, a 1.2 mm pitch, low-profile, swing-lock, wire-to-board connector that, while intended for general purpose power supply applications, is also ideally suited for use in solid state lighting. The connector has a height of just 1.4 mm and a footprint of 18 mm² or 23 mm² for the two- and three-position versions, respectively. The devices feature a unique swing-lock, double-locking mechanism that provides a reliable and secure connection. They have a positive lock that prevents accidental socket removal caused by cable pull, and a friction lock that prevents the socket from floating after mating. Despite their low-profile design, mating length is just 0.42 mm.

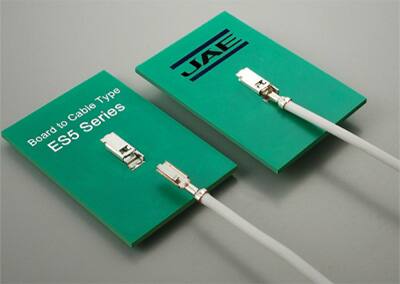

Also intended for wire-to-board applications, the ES5 from JAE is a compact, low-profile, one-pin cable-to-board connector designed specifically for use with stranded cables from 24 AWG to 28 AWG. The devices feature a mounted height of just 1.6 mm and a detachable locking structure with retention strength of 16 N. The ES5 series is rated for currents of up to 4 A AC/DC, and features a durability of 20 mating cycles. Contact resistance is 30 mΩ, and operating temperature from -40°C to 105°C.

Figure 6: The ES5 range from JAE offers low cost, small size and weight.

The great outdoors

Outdoor applications such as street lighting and event lighting, of course, have special requirements. What these two applications have in common is the need to resist dust and water ingress, often extending to complete immersion. Where the two differ tends to be in the number of mating cycles required, event lighting being essentially temporary and street lighting requiring much less frequent disassembly and re-assembly.

For these applications, Hirose recommends the HR30 or LF (miniature) series circular connectors, both of which are available with IP67 or IP68 sealing (resistant to total immersion).

The HR30 is short in length when fully terminated and mated. For quick assembly and disassembly, the connector is polarized to prevent misalignment or insertion of the wrong connector, and features a built-in lock/release mechanism that securely locks mated connectors, while allowing quick disconnection by simply pulling on the plug’s release collar. The collar itself is molded with grooves to prevent hand slippage when pulled, and the entire assembly is constructed from a glass-reinforced thermoplastic compound and is highly corrosion resistant.

Figure 7: Hirose’s HR30 series.

For applications where space is at a premium, the LF series devices combine high current rating (up to 10 A for a four-position connector) with small size. The connectors feature a short turn bayonet lock for easy assembly and vibration-resistant mating.

Conclusion

The advent of practical LED solutions has had a major impact throughout the design of lighting systems. Connector specification is no exception to this change: engineers have an increasing range of choices, both general-purpose and lighting-specific, when designing their systems. Selecting a range of products specifically optimized for solid state lighting applications can ensure appropriate performance, and may cut assembly costs. Against this, the designer may weigh the need to maintain stocks of more different product lines, as opposed to relying on solutions already in use in existing products.

The trend towards solid state lighting for controllability and sustainability is not the only force driving change, however. Increasingly, lighting is being used more creatively and thoughtfully, as architects and interior designers realize how illumination can enhance security, influence users’ comfort and productivity, and change consumers’ buying habits. There is, therefore, a great demand for convenience and comfort that is changing the whole approach to distributing power within a building – a profound change, brought about primarily by the desire to improve lighting systems.

Connector manufacturers have already responded with systems that offer standards compliance, small size, and easy assembly and installation: the next stage may well be the ability to combine power and control signal paths in a single wiring scheme, providing an even more flexible solution and paving the way to the truly ‘intelligent building.’

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。