Isolated DC/DC Converter Modules: Product Trends and Drivers

投稿人:电子产品

2011-11-01

Historically, the DC/DC converter module market has been applications-driven with sales to the communications segment leading the way. While this remains true, the computer segment also has grown rapidly in the last few years and overall the total worldwide revenue market for DC/DC converter modules is expected to reach approximately $4.3 billion by 2016, according to a June 2011 study issued by the Darnell Group.

There are a number of design criteria that an engineer must consider when selecting the appropriate isolated DC/DC converter for a project. Apart from the obvious requirement of converting a DC input voltage to a DC output voltage, the engineer’s must-consider list should include such factors as:

- The application. Strongly correlated with input voltages, the intended application has large implications for DC/DC converter design. The communications segment is dominated by 48 V, for instance, with 12 V dominant in computer applications. The industrial segment mainly uses 24 V input, medical input voltages are found in the 3.3 V, 5 V, 12 V and 48 V ranges, while higher input voltages prevail in the Mil/Aerospace market.

- The level of isolation needed. Although DC/DC converters exist without input-output isolation, most use an internal transformer, and the output is electrically (galvanically) isolated from the input to protect sensitive circuits from noise or high voltage. Adequate isolation may also be required to meet certain safety standards such as Underwriters Laboratory (UL) or CSA (Canadian Standards Association).

Gaining higher efficiency through regulated bus converters

It is not surprising that suppliers told us one of the most important specs that power designers care about when selecting a DC/DC converter is efficiency. For a given output power under certain conditions, the smaller the loss, the higher the efficiency and the lower the temperature rise.

"The most important value proposition is efficiency because it drives lower power consumption," says Karim Wassef, product line director, POL Products, Embedded Power BU, GE Energy, Plano, Tex. "Everybody is concerned with the energy waste of conversion and that's where efficiency becomes very important."

To meet the needs of power designers, GE Energy, formerly Lineage Power (GE Energy acquired Lineage Power in March 2011), developed the Barracuda series of fully regulated bus converters, which are designed to be high-efficiency and high-density solutions.

Lineage Power migrated to regulated solutions due to the industry's intellectual property litigation with SynQor. Historically, bus converters did not need to address regulation because that was handled by the POL converters.

Available in standard eighth-brick and quarter-brick DOSA footprints, the Barracuda modules can be used in "existing power designs as DOSA-compliant, drop-in upgrades for unregulated and semi-regulated bus converters challenged by recent industry-wide intellectual property issues," according to GE Energy.

In addition, the Barracuda series parts are available in digital and analog versions. "Digital has more feature capabilities but analog has a lot of backward compatibility to make it easy for engineers to use in existing boards," said Wassef.

Figure 1: The GE Energy Barracuda QBVW series is a drop-in alternative for unregulated and semi-regulated bus converter products.

The Barracuda series also offers very high efficiency for regulated products. These devices offer 96 percent efficiency at full loads. Wassef said these products are comparable in efficiency to the older unregulated parts. This is important because there is a bit of a negative stigma associated with regulation. "Being able to regulate means you cannot run at the bleeding edge of performance like an unregulated part," explained Wassef. "Why have regulation when you don't need it?"

However, the company discovered that when regulation and digital control are combined, the result is a new product that does something essentially different from products previously available in the market. Wassef explained one of the challenges for engineers when they design with isolated and non-isolated product is selecting the bus voltage between the two because they are trying to optimize efficiency.

"Traditionally, designers had to decide on the right bus voltage between the bus converter output and the POL input that would optimize performance and minimize the power consumption of a board. That's what you have to do with analog parts," Wassef said. However, with digital, designers can select the voltage they want to run at based on operating conditions.

"While having to regulate does reduce efficiency a little bit compared to unregulated bus converters, the ability to use digital to 'dial in' the right bus voltage actually buys back quite a bit in efficiency improvement versus an analog part that is set at one condition and can never deviate from it," said Wassef.

More emphasis on efficiency

GE Energy is not the only supplier working to improve efficiency. Other vendors such as Murata Power Solutions and CUI also are targeting high efficiency for their converter designs.

For example, Murata Power Solutions offers a highly efficient, fully isolated DC/DC converter with a typical efficiency of 90 percent. The open-frame UEE series devices are housed in a 58.4 x 22.9 x 10.16 mm (2.3 x 0.9 x 0.4 in.) footprint, meeting all the mechanical and electrical requirements of the industry-standard DOSA-compliant eighth-brick package.

The series is available in two models: the UEE-3.3/15-D48 with a 15-A output and the UEE-3.3/30-D48 with a 30-A output. Mounting options include through-hole pin or surface mount, and a base-plate option is available for the 30 A through-hole model.

Figure 2: The UEE series of highly efficient, fully isolated DC/DC converters from Murata Power Solutions offers a typical efficiency of 90 percent.

These low-profile converters offer a nominal input voltage of 48 VDC and can accommodate a wide input range from 36 to 75 VDC. They can operate from –40° to 85°C in telecommunications equipment when forced air cooling is applied. An output trim function allows the output to be adjusted ±10 percent of Vout nominal for voltage margining and to compensate for voltage drops within some applications, according to Murata. A Vout Sense function can also compensate for PCB losses.

CUI also offers a high-efficiency converter, which provides an ultra-wide input range. The company recently expanded its V-Infinity product line with the introduction of the VYB series of 4:1 input DC/DC converters that provide output power ranging from 10 to 20 W. These devices are available as 3.3, 5, 12, or 15 VDC single-output models and ±5, ±12, or ±15 VDC dual-output models.

In addition, they accept input voltages of 9 to 36 VDC or 18 to 75 VDC. Outputs are fully regulated to within ±0.5 percent over all line input conditions and ±1.0 percent for all load conditions.

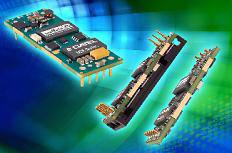

Figure 3: CUI's V-Infinity VYB DC/DC converter series is available in an industry-standard 2 x 1 in. footprint.

Packaged in an industry standard 2 x 1 in. footprint, the VYB devices are suited for battery-driven applications where charging and discharging conditions require an ultra-wide input range. With a temperature range of –40° to 85°C, the VYB10W, VYB15W, and VYB20W converters are suited for most operating environments, according to CUI.

Summary

From a product design perspective, DC/DC converter modules have become increasingly efficient and cost effective, with designs that are able to meet very specific system requirements. Choosing a suitable DC/DC power module can save engineers design time, debugging problems, and allow them to focus more on their field of applications. To help in the selection process, we have identified product development drivers-- from end applications to the ongoing need for increased efficiency-- providing specific examples and links to further information on the Digi-Key website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。